Overview: This turbo is for Fiat 0.9L TwinAir. It’s ideal for those looking for a quick responsive turbo for overall and top end power. It’s able to provide stable output in mid-RPM and all the way to the high peak. The maximum output is expected to reach 180hp.

Fits Vehicles:

- Fiat 500

- Fiat Panda

- Fiat Punto

- Fiat 500L

- Lancia Ypsilon

- Alfa Romeo MiTo

- Chrysler 200C EV (Concept)

Fits Codes:

- 55240093

- 55240093.01E

- 5524009301E

- 5524343

- 55243431

- 55243431.01E

- 552434310

- 5524343101E

- 552434331.01E

- 71795018

- 71795700

- 49373-03010

- 49373-03011

- 49373-03012

Features:

Direct Bolt-On: Can use the original car peripheral parts, easy and convenient to install.

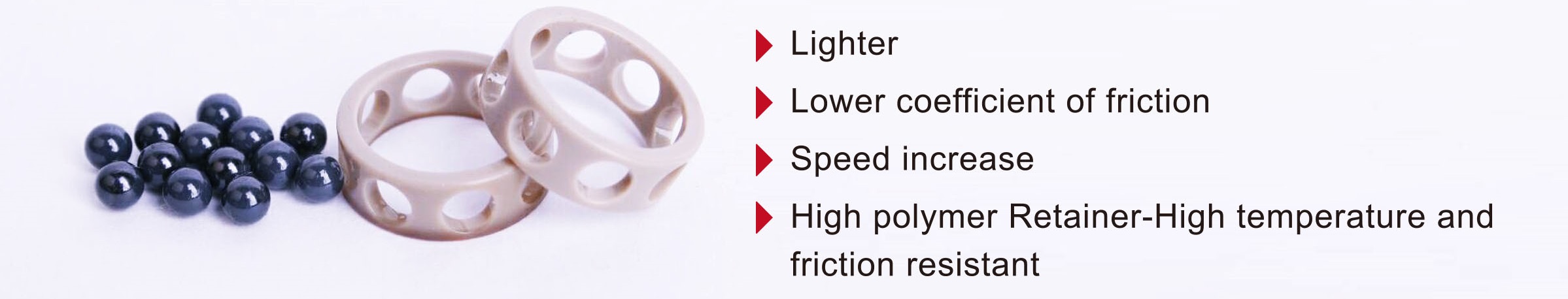

Dual ceramic ball bearing: The low friction allows the bearing to work at much lower required force and gives a boost at earlier RPM. The ceramic ball is made of Si3N4 high-precision fine ground ceramic ball. The spherical surface is in a perfect mirror state. With the match of the high-temperature, wear-resistant, shock-resistant and lightweight retainer cage, our bearings give an earlier boost than other ball bearings!

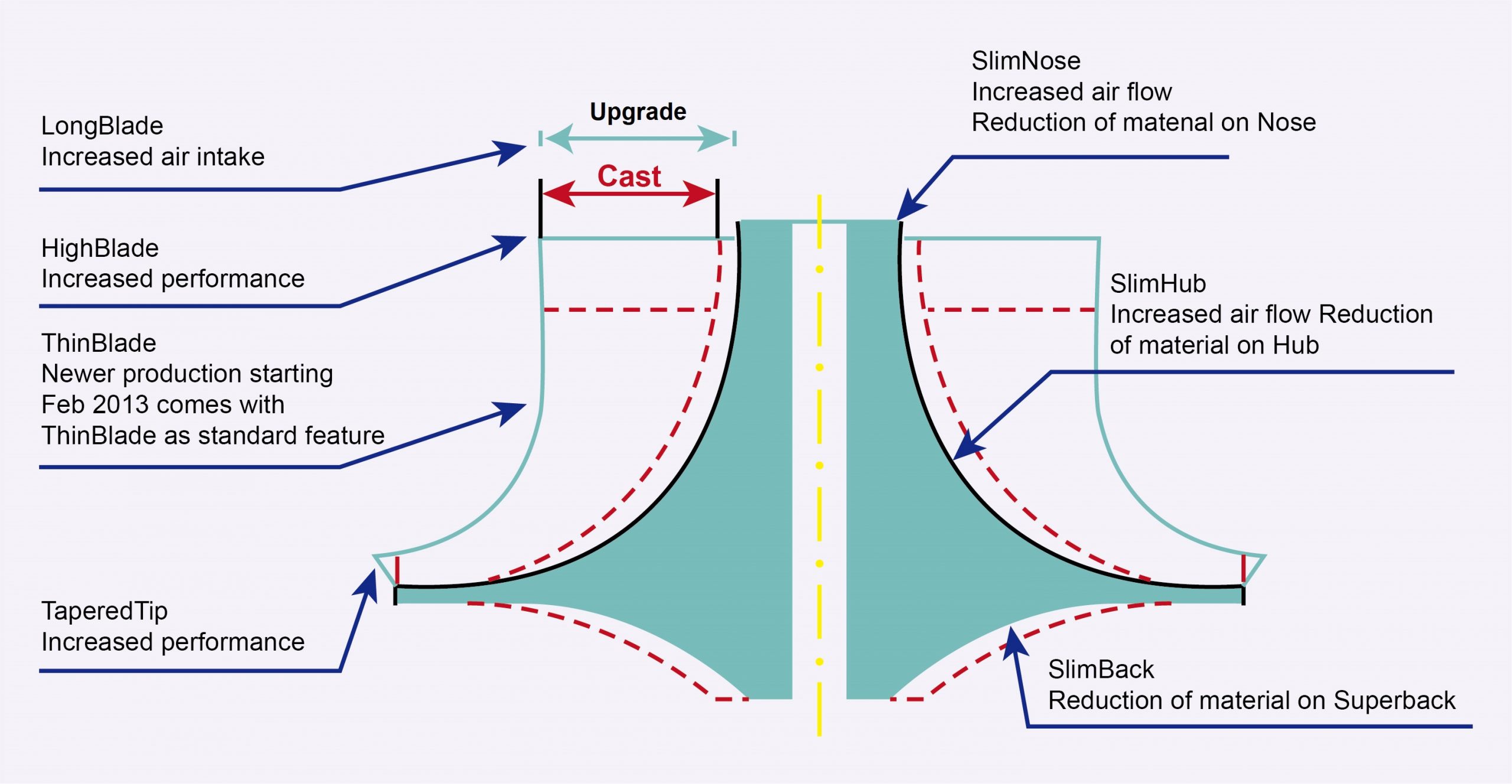

Upgraded Wheel: The upgraded aero grade aluminum billet compressor wheel allows higher intake air volume and improves air inlet efficiency. This upgraded high-flow turbine wheel comes with Inconel alloy. It consists of metal nickel as high as 70%, able to withstand higher temperature and pressure. As to the blade design, it offers much higher efficiency in terms of airflow, smoother exhaust and backpressure reduction. In return, we have much better wheel performance.

Housings: The turbine housing valve parts are made of heat-resistant, corrosion-resistant, high-strength alloy, which can withstand long-term high temperature and valve closing impacts. The exhaust housing is made of high temperature-resistant cast iron. It is able to withstand continuous extreme temperature and pressure.

Balancing: Precise balancing is one of the essential procedures in Amaker Turbo production. Due to a good balance is always an important factor in having an outstanding performance and reliability of a turbocharger. A good balance can also improve the noise generated by the high-speed operation. We have very strict operating standards for balance. First, we perform a low-speed dynamic balancing on a high-precision single-piece balancing machine in order to achieve the best balance of the parts. Secondly, we rigorously assemble the CHRA parts. After the assembly is completed, the high-speed dynamic balance is then performed. Our high-speed dynamic balancing machine can reach a maximum speed of 250,000 RPM. This balancing standard surpasses the OEM standards. Each turbo is accompanied by a serial number and the balance test result is kept in our database.